-

그렉 Henk당신의 상냥한 환대를 위한 감사합니다. 당신의 회사는 아주 직업적, 우리 가까운 장래에 있을 것입니다 좋은 협력이입니다.

그렉 Henk당신의 상냥한 환대를 위한 감사합니다. 당신의 회사는 아주 직업적, 우리 가까운 장래에 있을 것입니다 좋은 협력이입니다. -

Lionel Lobo좋은 서비스 및 고품질과 높은 명망을 가진 좋은 회사. 우리의 믿을 수 있는 공급자 중 하나는 때 맞추어와 좋은 포장, 상품 배달됩니다.

Lionel Lobo좋은 서비스 및 고품질과 높은 명망을 가진 좋은 회사. 우리의 믿을 수 있는 공급자 중 하나는 때 맞추어와 좋은 포장, 상품 배달됩니다.

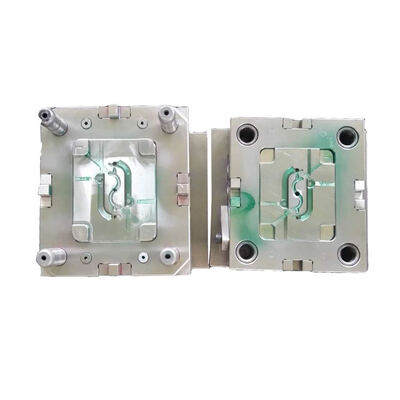

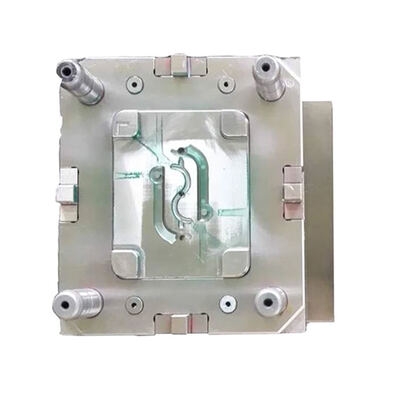

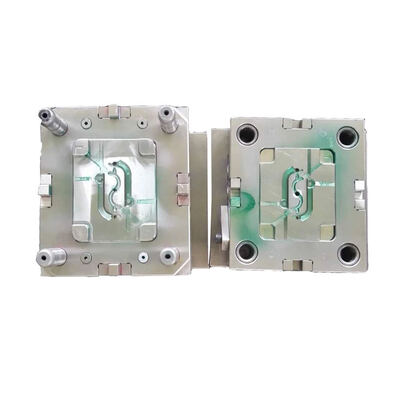

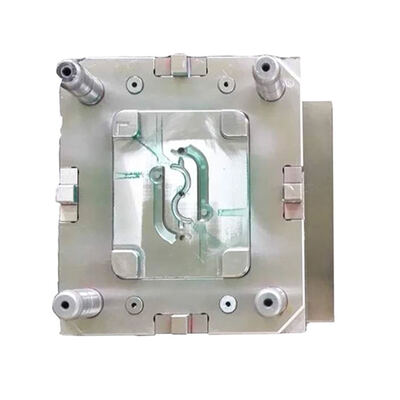

플라스틱 사출 성형 금형 제조업체 공장 가격 2 캐비티 4 캐비티 8 캐비티 핫 러너 사출 금형

| 제품명 | 멀티캐비티 주형 | 맞춤형 | 예 |

|---|---|---|---|

| Demoulding | 오토매틱 | 견고성을 사용하기 | >HRC45 |

| 금형 수명 | 50,000-100,000은 쇼팅시킵니다 | 곰팡이 재료 | EPS |

| 표면 처리 | 열처리 | 평균 벽 두께 | >3mm |

| 제품군 | 자동차 부품, 조명, 산업, 가구 | 유형 | 소실 발포체 캐스팅 |

| 강조하다 | 보증이 있는 플라스틱 사출 성형 금형,멀티 캐비티 핫 러너 사출 금형,2 구멍 플라스틱 주사 곰팡이 |

||

플라스틱 사출 금형 제조업체 공장 가격 2 캐비티 4 캐비티 8 캐비티 핫 러너 사출 금형

저희 금형 제조업체에게 멀티 캐비티 금형은 효율성, 정밀성, 비용의 궁극적인 교차점입니다. 이는 정밀한 핫 러너 선택, 과학적인 러너 설계, 균형 잡힌 냉각 레이아웃, 가장 적합한 강철 및 열처리 공정 선택에 이르기까지 체계적인 엔지니어링 능력을 시험합니다. 고객에게 안정적이고 효율적인 멀티 캐비티 금형 세트를 성공적으로 제공하는 것은 '도구'를 제공할 뿐만 아니라 장기적인 시장 경쟁력을 구축하는 데 도움이 됩니다.

특정 제품이 있는 경우 멀티 캐비티 설계를 달성하기 위한 가능성, 잠재적 과제 및 가장 비용 효율적인 솔루션에 대해 함께 논의할 수 있습니다.

금형 제품 범위

운송, 농업 기계 장비, 건설 기계, 수자원 시설, 우주 항공, 화학 기계, 해상 운송 등.

금형 특징

- 정확성과 안정성 치수

- 쉽게 조립 및 분해 가능;

- 낮은 유지 보수

- 더 긴 수명

- 미세 마감

- 고강도

- 견고한 디자인

- 내구성

제품 설명

|

제품 이름

|

알루미늄 금형 다이캐스팅

|

||

|

크기

|

맞춤형

|

||

|

색상

|

요구 사항에 따라

|

||

|

재료

|

알루미늄

|

||

|

응용 분야

|

자동차 부품, 조명 기구, 램프 커버, LED 조명 하우징, 방열판 또는 기타 유형의 다이캐스팅 부품

|

||

|

서비스

|

OEM/ODM

|

||

|

제품 디자인

|

고객의 도면 또는 샘플에 따라 맞춤형

|

||

제조 공정1. 고객의 부품 설계, 도면 및 품질 표준 검토.

2. 금형 및 툴링 설계 및 제조

3. 금형 및 툴링 테스트 및 샘플 확인

4. 다이캐스팅 원시 주물

5. 표면 처리: 트리밍, 디버링, 연마, 세척, 패시베이션 및 파우더 코팅 및 고객의 기타 요구 사항

6. 정밀 가공: CNC 선반, 밀링, 드릴링, 연삭 등

7. 전체 검사

8. 포장

9. 배송

핵심 과제 및 솔루션

- 일관된 충전 및 압력 유지: 유로가 균형을 이루더라도 각 캐비티의 미세한 차이(연마, 배기, 냉각)로 인해 불일치한 충전이 발생할 수 있습니다. 제조 전에 금형 흐름 분석 소프트웨어(예: Moldflow)를 사용하여 시뮬레이션, 문제 예측 및 최적화를 수행합니다.

- 균일한 냉각: 멀티 캐비티 금형의 냉각 설계는 "도시 계획"과 같습니다. 각 캐비티, 특히 코어(이동 금형) 측면이 동일한 양의 냉각을 받도록 하는 것이 필요합니다. 직렬 연결로 인한 불충분한 끝단 냉각을 방지하기 위해 병렬 냉각 회로와 모방 수로가 자주 사용됩니다.

- 금형의 강성 및 수명: 더 많은 캐비티는 더 큰 템플릿과 더 복잡한 내부 구조를 의미합니다. 우리는 사전 경화된 금형 강철 또는 H13 유형의 열간 가공 강철을 사용하고 채널 교차점 및 작은 코어와 같은 중요한 위치에서 특수 열처리(질화)를 수행하여 장기간의 교번 응력을 견디고 조기 균열 또는 마모를 방지합니다.

- 배기의 미세 관리: 각 캐비티의 배기는 독립적이고 충분해야 합니다. 우리는 파팅 표면, 탑 핀 및 인서트에 신중하게 계산된 배기 홈을 설정하며, 깊이는 일반적으로 0.01-0.03mm로 정확하여 가스가 배출되고 플라스틱이 넘치지 않도록 합니다.

회사 프로필

Luoyang Liushi 금형 Co., Ltd는 2001년에 설립되었으며, 로스트 폼 주조 금형에 대한 국가 표준 설정 단위입니다. 회사는 천년의 황제, 모란 꽃 도시인 뤄양시에 위치하고 있습니다. 우리는 9800개의 사무실 건물과 22000개의 작업장을 보유하고 있으며, 연구, 개발, 설계, 주조, 가공, 조립, 표면 처리 및 기타 장비를 잘 갖추고 있습니다. 뤄양시 R&D 센터 및 기술 센터입니다.

![]()

회사 기술자는 고객의 요구에 따라 로스트 폼 주조 공정에 대한 현장 가이드 금형 조립, 테스트 생산, 무료 수리 및 완전한 기술을 제공할 수 있습니다. "신중한 설계, 린 제조, 최고의 서비스, 완벽한 품질"의 비즈니스 철학으로 고객에게 만족스러운 제품과 서비스를 제공하기 위해 노력합니다. 수년간의 개발 끝에 우리 회사는 많은 로스트 폼 주조 제조업체의 선호하는 금형 공급업체이자 독점 공급업체가 되었습니다.